Technology, Teamwork and Solutions

Concepts & Consulting

How many cavities does the mold need to have to meet production demands? How large should the runners be? What type of plastic will you be using? How large will the machine need to be to run the parts? What is the production volume needed from the mold? These are just a few questions that need to be answered when designing precision tooling. Jedlick Molding will help your company answer these questions and design a mold that is just right for your needs.

Prototyping

So you have an idea, but you need more than a picture or CAD drawing to sell the idea. This is where prototyping comes in. Prototyping can be done in many ways. We can assist your company with choosing the right method for each project.

Injection Molding

Our molding department uses closed loop molding machines. The molding department is capable of molding parts with extremely tight tolerances and dimensional requirements. We run most all thermoplastics materials, with a specialized area of engineering grade and filled materials. Material used are ABS, acetal, polypropylene, polyethylene, polystyrene, nylon, PET, PBT, elastomers and urethanes to name a few. Many additives are also used such as customer colors, fiberglass, mineral filled, UV stabilizers, flame retardants and FDA approved materials.

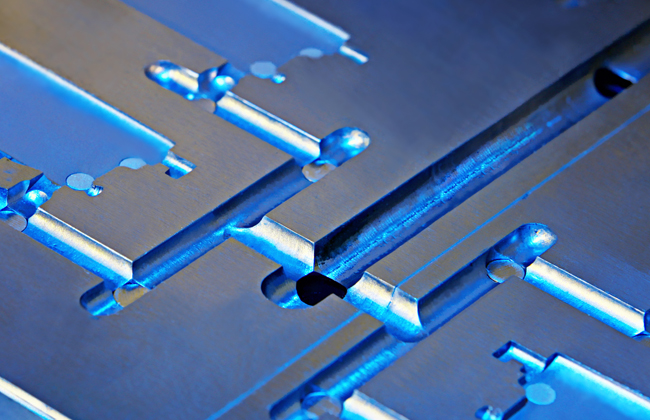

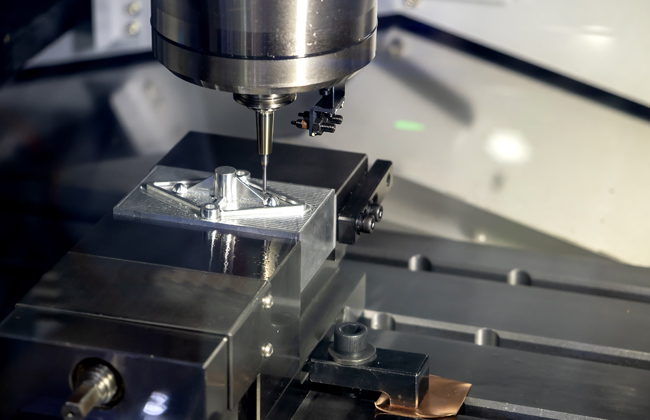

Mold Making

We can provide your company with precision tooling to meet your specific application. Whether its a short run project requiring aluminum tooling or or a hardened steel mold capable of producing millions of parts, we are capable of creating what you need.

Assembly and Distribution

Jedlick Molding will check your parts for quality, assemble, and package your products specifications. Each customers needs are different. We are focused on meeting those needs as each customer defines them.